Equipment

FiberTech Lille brings together, in one place, state-of-the-art skills and equipment dedicated to the manufacture of high purity glass preforms by Modified Chemical Vapor Deposition (MCVD), Outside Vapor Deposition (OVD) and Sol-Gel (hydrolysis-condensation at low temperature). But also equipment specially developed for the realization of micro-structured PCF fibers (also known as hole fibers), associated with tools for characterization and modeling of fibers. These tools make this platform a unique site in France and world class.

Equipment dedicated to the manufacture of glasses of high purity: 3 complementary manufacturing methods.

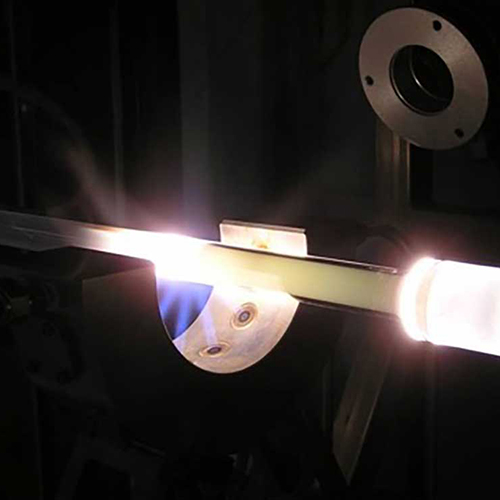

MCVD

An MCVD frame: internal gas phase deposit by the oxidation of halides.

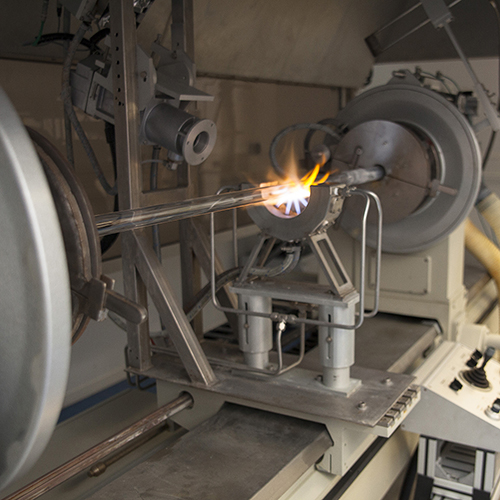

OVD

An OVD frame: external vapor deposition by hydrolysis of halides.

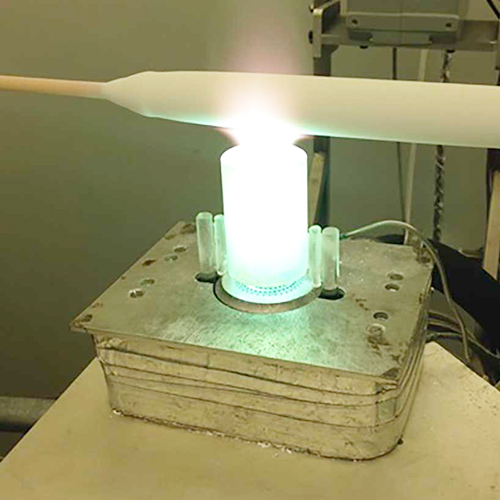

Sol-Gel

A set of fume cupboards and ovens dedicated to manufacturing by Sol-Gel process.

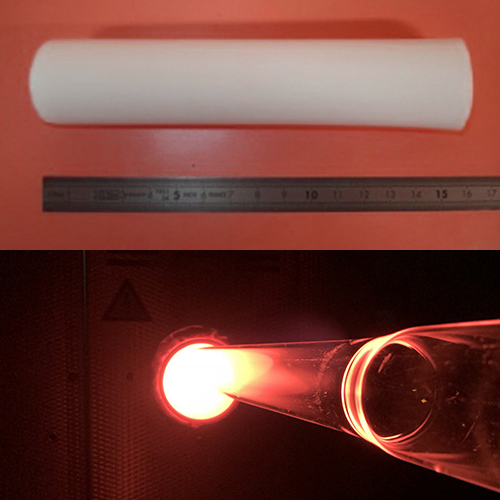

Examples of originality:

Dopage rare au sol en phase vapeur, contrôle précis de la porosité avant densification, dopage exotique (nanoparticules)…

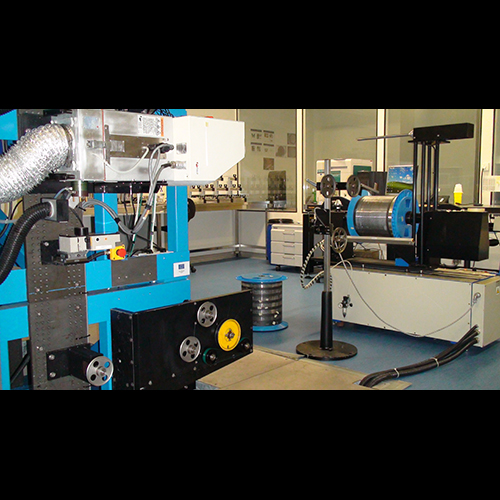

Equipment dedicated to the production of optical fibers: 3 additional draws in the "white" room.

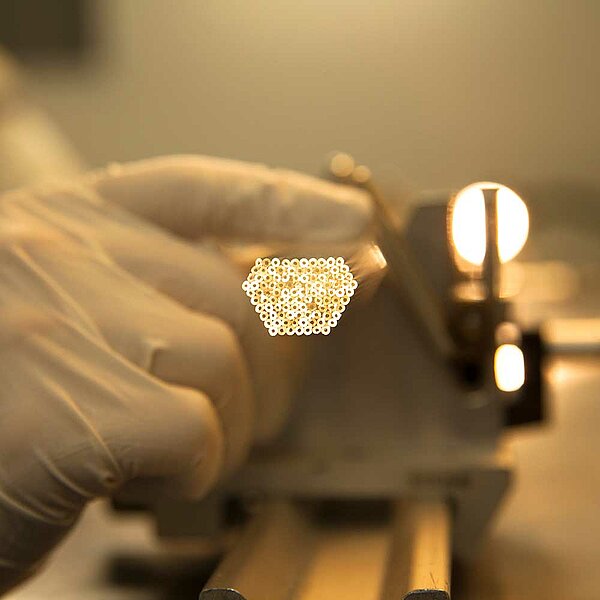

Capillary stretching and assembly tower (8m):

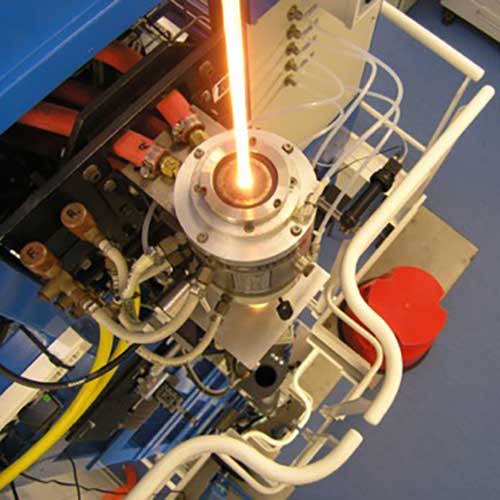

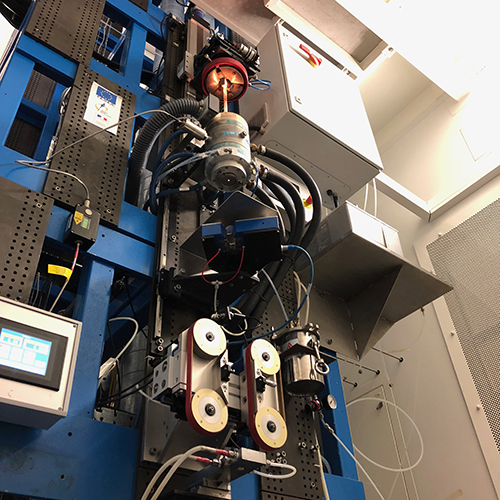

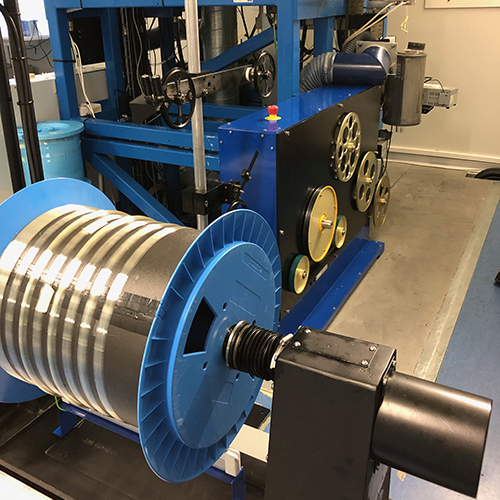

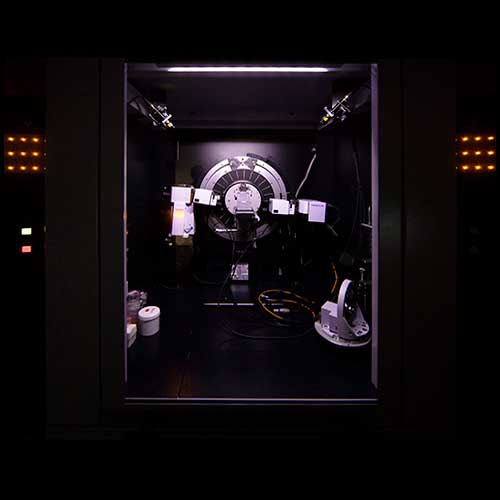

Uniform and topographic fiberization tower (12m):

Draw tower and development fiberization (4m):

Examples of originality:

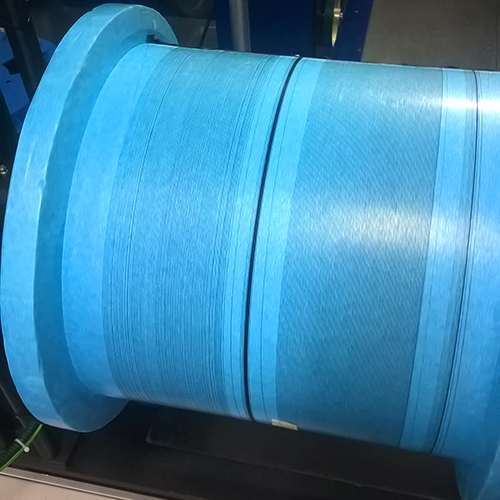

"Topographic" fibers (controlled longitudinal variations), random multicore fibers, millimeter fibers, 1000-hole fibers, laser insolation during fiber drawing and coating for severe conditions...

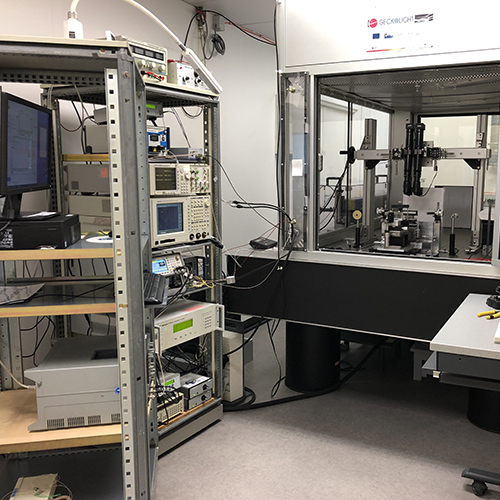

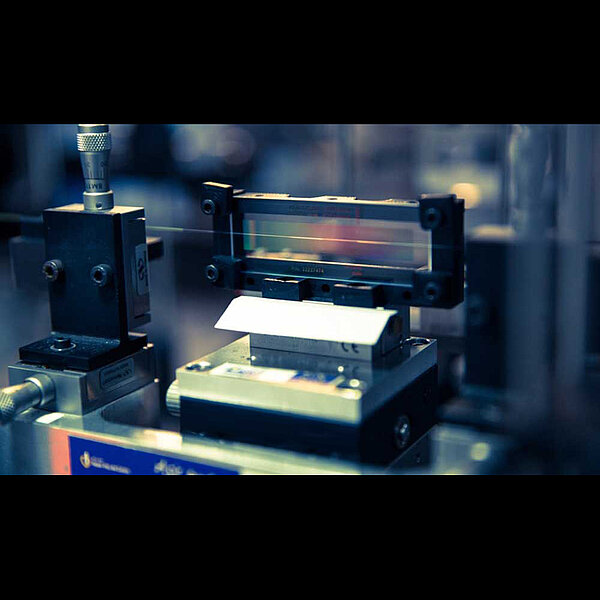

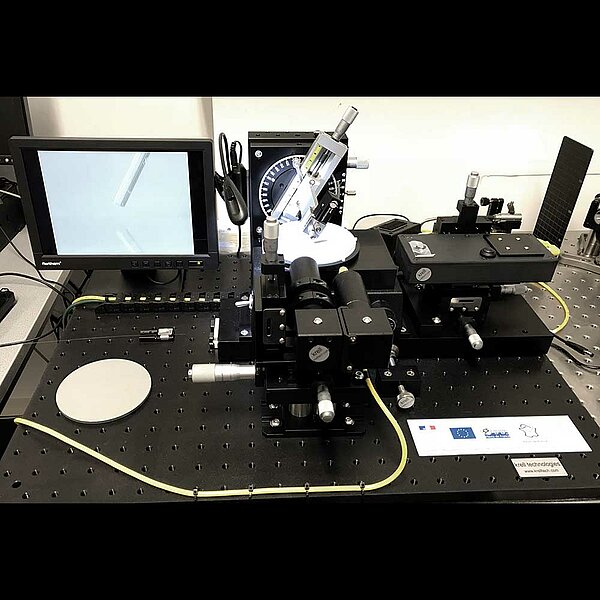

Bragg Networks equipment:

- Registration phase mask of Bragg networks.

Post-processing equipment:

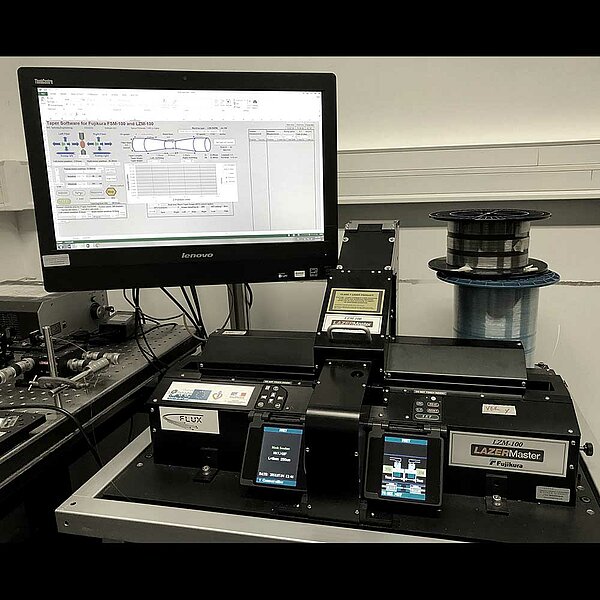

- A fleet of arc and filament welders.

- A LZM100 CO2 laser welder (splice, type, combiner, endcap).

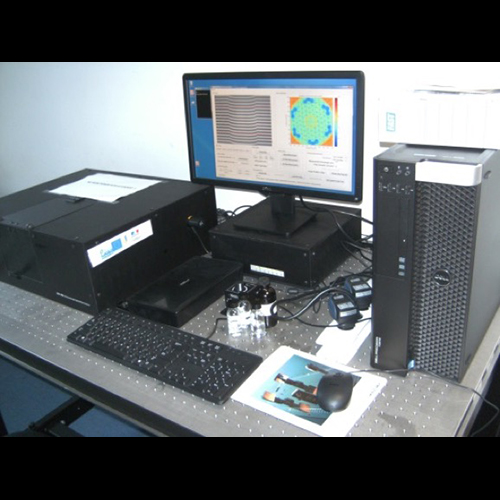

Characterization equipment:

- Fiber Index (IFA) Profile Analyzers and Preforms.

- SEM (Scanning Electron Microscopy) and an X-ray diffractometer.

- A light scattering measurement system on preform and optical fiber.